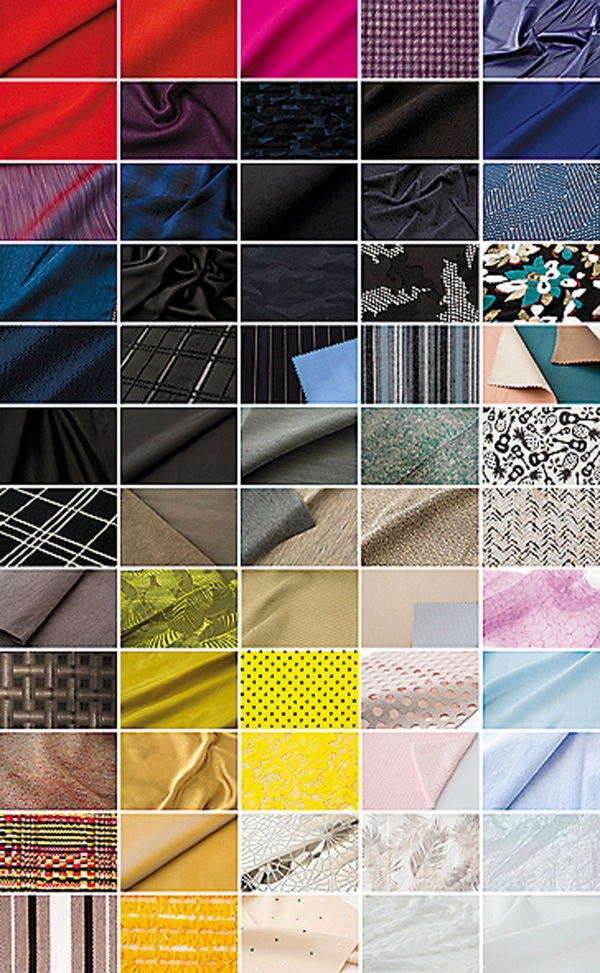

Theme 2 Assemble

Here we see twisting, mixed weaving, and the knitting together of different materials. Rather than interweaving the materials in a disorganised way, these methods allow fabrics to coexist without destroying their individual characteristics, creating a new harmony. Although this form of expression was also visible in the A/W 16/17 collection, it appears to have since become more sophisticated and widespread. The combination of different surfaces – such as pairing a shiny satin surface on the face with a matte surface comprised of textured woven fabrics (dobby weave) on the reverse, or matching a multi-structured jacquard that incorporates different forms with the three-dimensional surface effects created by a mixed weave of stretch yarn and straight yarn – communicate the appeal of the fabric.

■Combination of materials

Toray Ultrasuede: The bonding of perforated artificial suede and transparent organdie. This material is characterised by its shine, reversible colour-blocking, and texture (face: polyester 80%, polyurethane 20%; reverse: polyester 100%)

Uni Textile Co Ltd: Delicate separated single filament yarn and the uneven yet att-ractive texture of heavyweight cotton are woven together to create a new texture (polyester 51%, cotton 49%)

Chugai Kunishima Corporation: Twisting together PVA and linen through tri-spinning creates a texture and surface not found in typical three-ply fabrics (linen 100%)

Tatsumi Weaving Co Ltd: A double-weave fabric woven by alternating between single strands of cotton and polyester on the warp. Separate dyeing processes result in a reversible fabric (cotton 60%, polyester 40%)

Toray Synthetic Textile Cluster (Tec One): Using a nylon fully dull yarn for the warp and a combination filament yarn of nylon and cation for the weft, the goal was to produce surface changes through the mottled feel of the yarn and the jacquard weave (nylon 84%, polyester 16%)

Nakaden Keori Co Ltd: A mixed weave comprised of uniquely-spun wool- and cotton-type materials with both long and short fibres that can be blended uniformly. The quality, delicacy, and lightness of the raw materials remain present in the fabric (wool 27%, cotton 29%, polyester 44%)

Yagi Tsusho Ltd: A camouflage pattern is created through the opal printing of three-layer bonding. The combination of different textiles creates a complex pattern (cotton 60%, linen 20%, polyester 20%)

■Combination of weaving, knitting, and processing

Takihyo Co Ltd: Yarn harnessing the colouring schemes of morpho butterflies is used in the traditional craft of Nishijin weaving. A brilliant and contemporary aurora-like lustre emerges from the traditional lattice pattern (silk 74%, polyester 26%)

Yagi Tsusho Ltd: Traditional yoryu fabrics feature a series of compressed and non-compressed sections, resulting in three-dimensional patterns (polyester 100%)

Chugai Kunishima Corporation: Partially double-woven, this fabric incorporates a plaid pattern and grand steps. Dyeing in multiple colours is also possible (cotton 91%, polyester 9%)

Toko Shoji Co Ltd: Switching between a twill pattern inlay and tenjiku cotton results in a material with a multi-border pattern and a rich expression (cotton 100%)

A-Girl’s: After knitting together a unique yarn with a cotton core and ultrafine monofilaments on a high-gauge knitting machine, opal printing is carried out to create a delicate yet transparent surface (cotton 70%, polyester 30%)

LIVINAX by Itochu Corporation: Equipped with a suppleness and power stretch performance achieved through the use of thick nylon yarn, this bold mesh created using a middle-gauge raschel knit is intended for use in outerwear. (nylon 88%, polyurethane 12%)

Yoshida Senko CO., LTD: Made using a three-ply cotton yarn dyed in-house, this simple yet reversible material contains colour effects and a structural organisation that produce rich and changing expressions on the surface (cotton 100%)

Matsubun Textile Co Ltd: A gentle swell produced through multilayer twisted yarn coexists in this fabric with a lovely weathered feeling as a result of multiple weaving

Toray Synthetic Textile Cluster (Komatsu Seiren): Using knit material produced with split-fibre yarn for the surface and finished with a suede tone through special processing, the lightweight backing material is then subjected to further bonding in order to create the fabric’s dual character (polyester 59%, nylon 38%, polyurethane 3%)

Hokko Co Ltd: Aurora foil is printed onto a menswear-like base material with a vintage feel, giving the fabric a genderless expression (cupro 100%)

■New categories created through the combination of technologies

Cloth, or knit?

Yagi Co Ltd: Using 40-gauge stretch ponte, which is difficult to knit, tension and stiffness are created through special processing, finishing with a product that resembles cloth (cotton 44%, nylon 55%, polyurethane 1%)

Nakaden Keori Co Ltd: Made using a flat-knitting machine that can carry out weft insertion, this knit has an appearance and texture that resembles cloth. There is a sense of firmness in the crosswise weave, and it is finished beautifully in a way that prevents it from going limp during the apparel manufacturing process (cotton 61%, nylon 28%, linen 11%)

Hironen co., LTD: PTT fibre and hemp mixed yarn, which are extremely difficult to knit, have been knitted here using fine gauge, creating a denim-like material (linen 34%, cotton 34%, polyester 32%)

Corduroy, or jacquard?

Fukuda Orimono,LTD: The next-generation textile BECCO has an uneven texture created by applying the core weaving technology used for corduroy. With a voluminous softness and firmness, this material also features superb design performance (cotton 100%)